Who Are We?

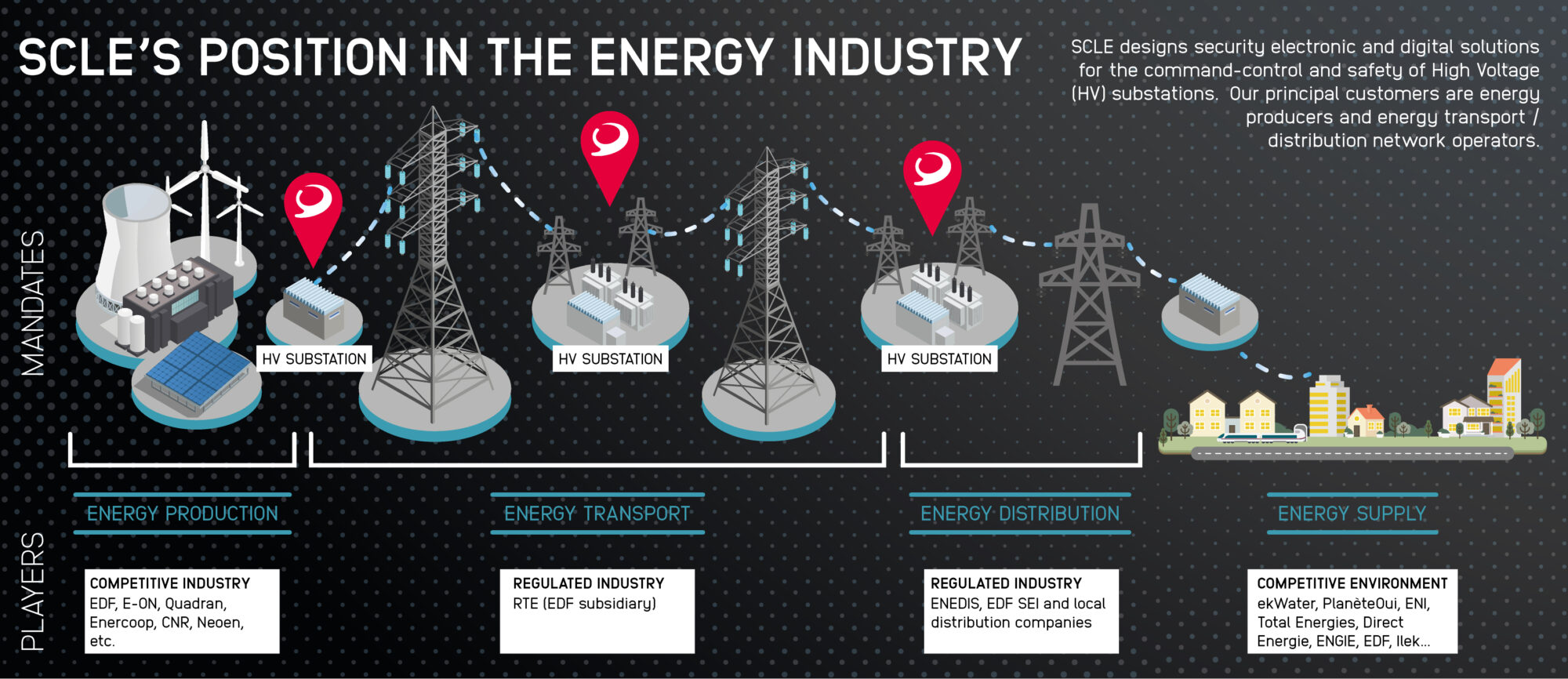

SCLE is a high-tech company specialized in IT and electronics for Energy and Rail.

A human, technical and technological adventure spanning 50 years

Our company has its roots in energy—what better source of inspiration to reinvent ourselves?

Since its inception, our business has branched out from electrical networks to rail networks, with catenaries providing the obvious linchpin between the two.

Moving forward, reinventing ourselves, breaking new ground—one step at a time—takes time. Innovation takes time. Luckily, we have it.

At SCLE, sustainability is key; reliability a mindset.

That means we’re here to last in terms of:

• The products we deliver

• The people who work for us

• The relationships we forge with our partner-customers

We can see far into the future, allowing us to take the time to do the job well and to build relationships with customers on solid foundations.

Highly qualified in electrical energy and rail transport

SCLE is a high-tech company specialized in IT and electronics for energy and rail.

We build electronic and computer equipment for high voltage (HV) and rail substations to serve national and international customers working in the fields of electricity and rail transport.

Unique and integrated End-to-End Offer

SCLE employs 320 men and women, based at our sites in Toulouse and Marseille. Both sites provide access to the full spectrum of technical expertise required to implement the broad range of unique products and services we offer our customers.

Our end-to-end solutions and services guarantee long-term customer support and a strong commitment to providing robust, high-quality and sustainable products.

Full and optimized life-cycle support

At SCLE our value proposition is to design, manufacture, install and maintain our products throughout their life cycle.

Our turnkey solutions designed alongside customers and produced in our workshops by our technicians and engineers are open-ended, enabling them to be upgraded after installation to meet future technological and/or functional developments.

Our products meet current specifications and future requirements. They are interoperable and open-ended, therefore sustainable.

End-to-end solutions

SCLE is created in Toulouse …

SNCF celebrates its 31st birthday, whilst André Coudé du Foresto founds SCLE to refurbish and modernize the railway network of the French southwest.

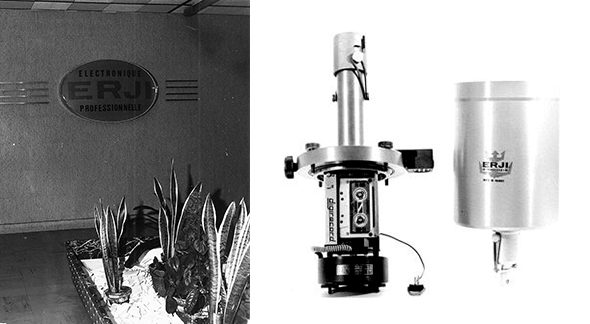

… and ERJI Agence in Marseille

Jean Robert founds ERJI the same year. The first products are underwater exploration cameras capable of going to a depth of -6,000m!

Manufacture and integration of classic substation chassis

The boom in telecoms spikes demand for relay racks creating the opportunity for SCLE to manufacture and integrate conventional substation racks.

Design of the first SCLE product: the RH

The boom in the electronics industry inspires Jean-François Revel to design the RH system.

Acquisition of ERJI

ERJI joins forces with SCLE to advance the growing sectors of energy and rail.

Start of the PCCN offer

The IT revolution is underway, and workstations are going digital: SCLE designs the first PCCN equipment on the market.

ARKENS range

The ARKENS range enables operators to maintain electrical networks remotely.

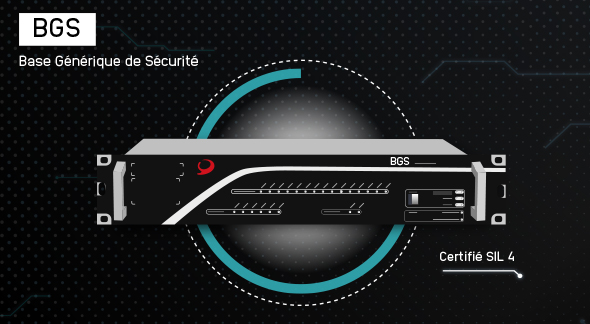

BGS SIL4 Certified

SCLE stands out at European level for the digitalization of railway signaling, when it achieves the highest security level rating for its BGS platform.

RTE Ringo Project in Ventavon

Ringo places renewable energies at the heart of grid flexibility!

Our certifications